Lean Intuitive Planning Case Study

Appointed by a Manufacturing Company to understand their current usage of their existing Property, Logic PM undertook a detailed survey of the building and all the internal components and machinery to evaluate the production and administration space for this manufacturing client.

To truly understand how the manufacturing spaces interacted with the other critical parts of the building our in house design managers converted the survey information in to an existing 2D drawing. This showed how he separate departments interacted with each other and highlighted the storage facilities within their existing space.

In order to understand how to improve their business function and in conjunction with the operation team, our design team showed how as part of a LEAN initiative programme material flow and output can be improved within the building.

Taking this one stage further, using the client knowledge of their production methods, Logic PM optimised the layout of the existing space and showed how manufacture performance could be improved by the relocation of machinery and storage to improve the bottom line.

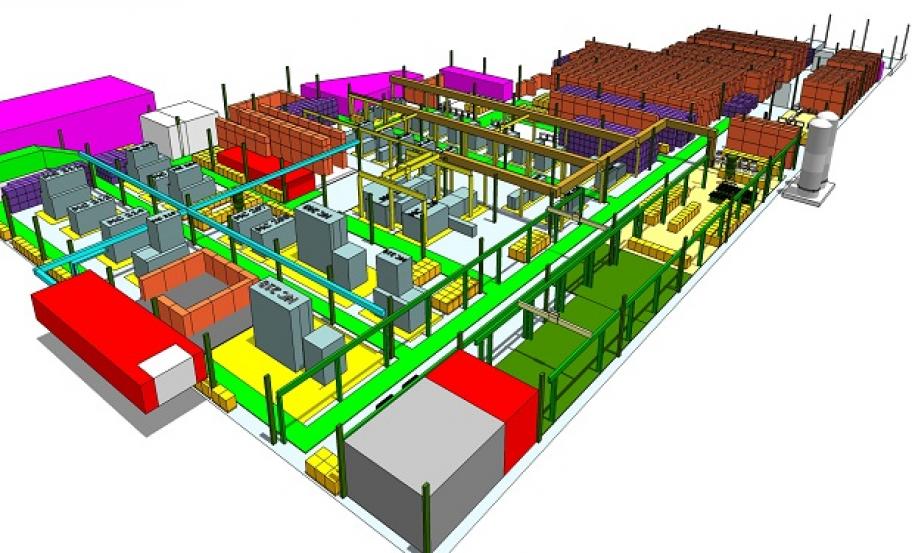

As some people are not able to read drawings easily, we created a 3D model of the space and how the new optimised space would look to enable all members of the business to comment on the proposed layout. Using various techniques and walkthroughs of the created model all members of staff were invited to offer comment on the new layout to ensure complete staff buy in.

This model and information was then turned into a series of drawings and specification to allow our cost engineers to create a budget cost pan for the works and allow the client to seek funding from the parent company to facilitate the works.

This is not the first project where Logic PM have intuitively worked with the client to fully understand their ethos and maximise their floor layout to not only suit their property but also to improve costs in the production of their products and services.

We are currently in discussions about the next stages of the project with the client and hope to provide an update shortly. However, this is an exciting journey we have joined our client on and helping them streamline over 30,000 s ft of floor space which is no longer required and improves business efficiency and output.